Boiler maintenance to-do list

August 30, 2018 | By Tim Kane

One of the biggest thieves of efficiency in boiler operations is the accumulation of soot and/or scale on heat exchanger surfaces. It does not take long for soot to start causing significant loss of energy efficiency.

In a matter of just a couple of weeks, there could be a potential of 1/8 in. of soot on equipment stemming from regular usage, which means lost efficiency and overspending in utility costs.

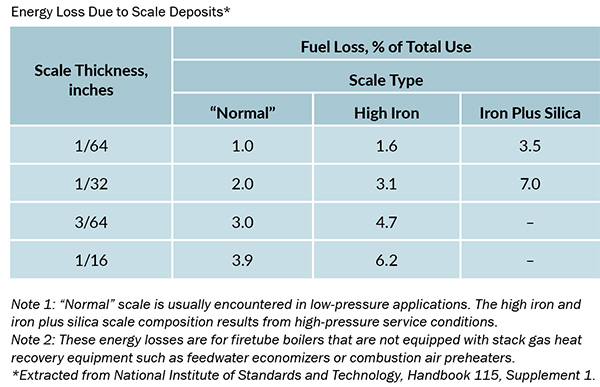

Scale can also accumulate quickly and add unnecessary operational expenses.

According to the U.S. Department of Energy, fuel consumption could increase as much as five per cent in firetube boilers as a result of scale.

According to the U.S. Department of Energy, fuel consumption could increase as much as five per cent in firetube boilers as a result of scale.

Routine maintenance and cleaning is the most beneficial way to keep boilers healthy and running efficiently. Performing this maintenance at least once a year is an investment that will pay off.

TIPS FOR A HEALTHY BOILER

- Stick to an Inspection and Maintenance Schedule – At least once a year qualified on-site personnel or a third party should inspect and clean all parts of the boiler. Contractors may create a maintenance plan to be done internally or do the work themselves. It is important to have a solid schedule in place to keep clients on track.

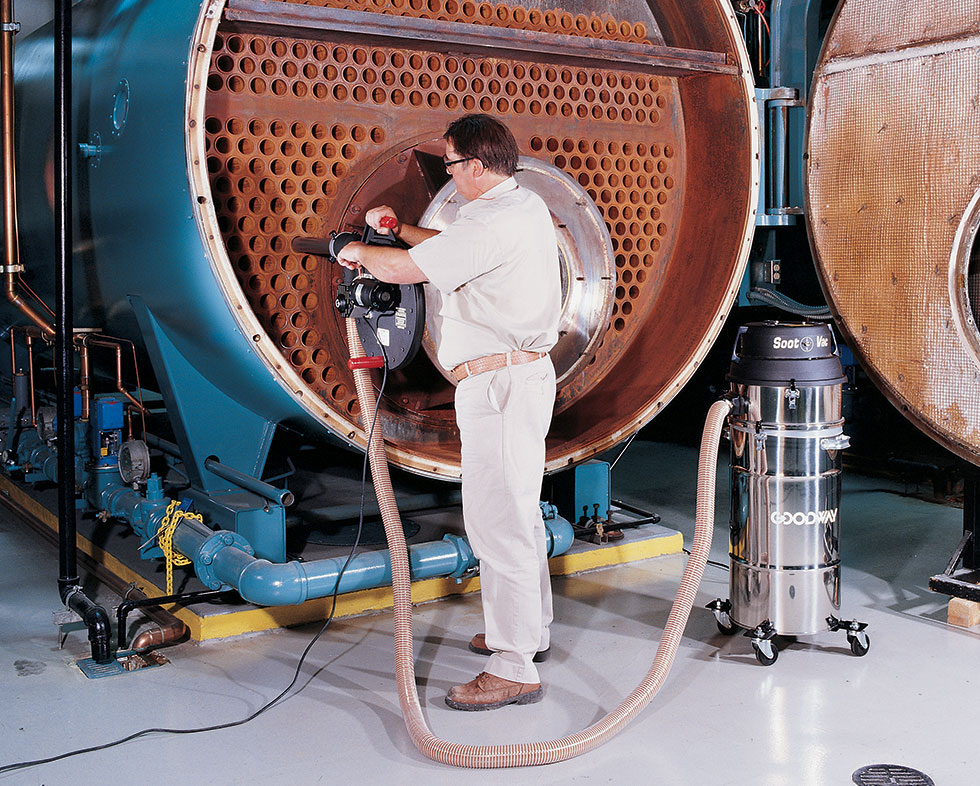

- Review the Chemical and/or Mechanical Cleaning Solutions – You will notice a significant reduction in operating costs by removing the contaminants on both the waterside (scale formation) and the fireside (soot and scale formation) of boilers. While mechanical cleaning typically utilizes moving brushes to remove scale from the walls of tubes and pipes, the chemical process uses a chemical solution to flow through the tubes dissolving and flushing out the scale.

- Maintain Daily Logs – Most problems develop slowly, therefore a log is the best way to detect significant changes. Have the facility manager keep daily logs on the following: type and amount of fuel used; flue gas temperature; makeup water volume; and steam pressure, temperature, and volume. Ongoing logs will help monitor for any potential issues that might develop or identify problems that could be fixed with proper cleaning.

- Perform Visual Inspections – Look at the boiler tubes and conducting a visual inspection to check for scale accumulation on a more frequent basis to help ensure the boiler tubes are free of scale and buildup.

Tim Kane is president of Goodway Technologies. Editors note: For more information on the effects of scale and corrosion see Modern Hydronics Part I and II 2017 at www.hpacmag.com (How water behaves).